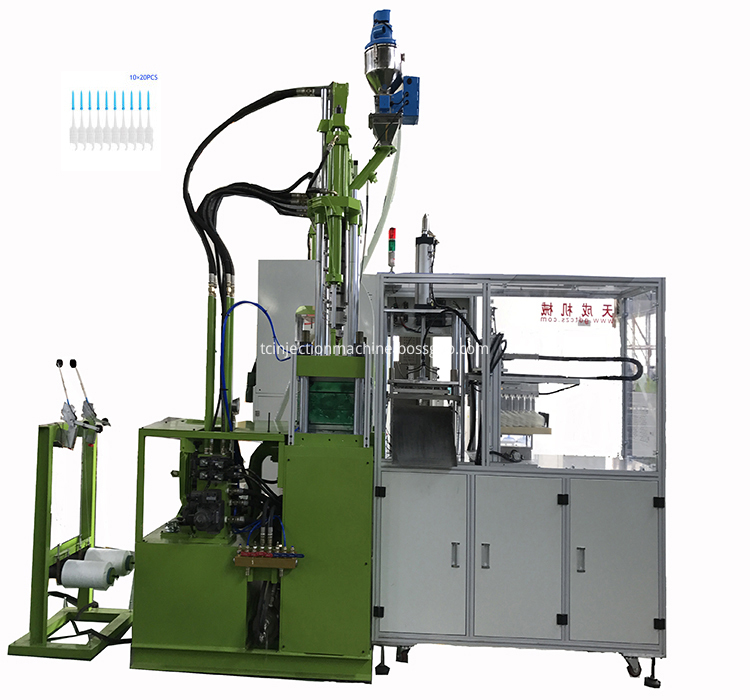

Glide Dental Floss Toothpick Injection Moulding Machine

Basic Info

Model No.: TC-450-P

Product Description

Fully Automatic Dental Floss Pick Injection Moulding Machine

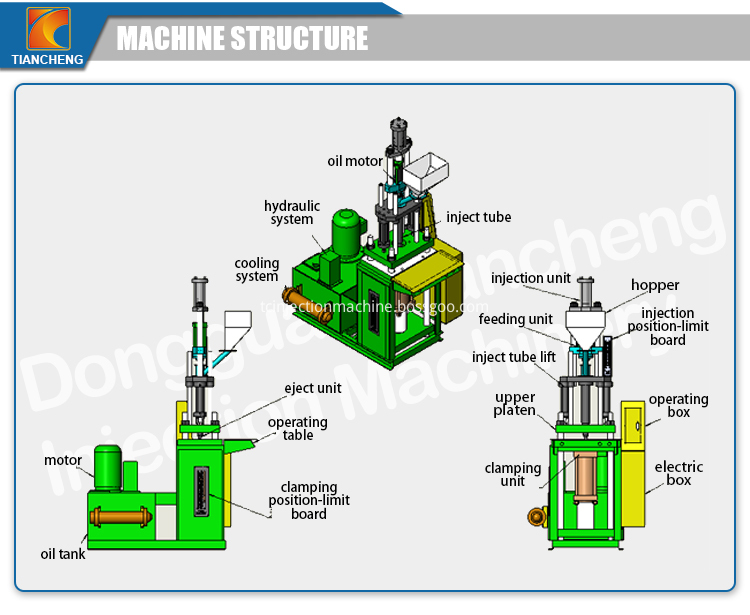

Due to technicians are constantly learning new technologies, our company can continue to develop new injection machines to maintain market competitiveness. Just as this Dental Floss Pick Injection Moulding Equipment, the upper mold is movable and the lower die is fixed, which is propitious to position for the finished product in the mould. Also, it is very convenient to take out the end product from the Hydraulic RAM. In addition, owing to two nozzle devices of this Glide Floss Pick Injection Moulding Machine use guide rail cylinder of famous brand, such as SMC, the operation is more reliable and stable.

Product Description

Main Features

1. Vertical mould clamping/ vertical injection moulding, 4-section temperature control, and stepless adjustments for injection pressure / injection speed / back pressure.

2. Reliable automation driven by famous brand cylinders such as Airtac and SMC, can pull the dental lines, cut the dental floss, and separate the runner automatically.

3. Suckers take the dental floss and drop down on collecting sticks neatly, which is easy to take out for packing. When the collected dental floss reaches the set quantity, tips on controller

screen will remind you to shift the empty collecting sticks.

4. There are two solutions, first one can make to 16 floss per cycle, while the other one can make up to 60 floss per cycle.

Specifications

MODEL UNIT TC-450-P

INJECTION UNIT Screw Diameter MM 28 32 Maximum Injection Pressure Kg/Cm2 1999 1742 Theoretical Shot Volume Cm3 73 96 Maximum Shot Weight(PS) G/oz 65/2.2 85/3.0 Injection Rate Cm3/sec 58 76 Screw Speed R/Min 0-180 Screw Stroke Mm 120 Nozzle Stroke mm 220 Number of Temperature Control _ 3

CLAMPING UNIT Clamping Force Ton 45 Opening Force Ton 7 Platen Size MM 500x360 Slide Stroke MM / Rotary Table Diameter MM / Space Between Tie-Bar MM 370x210 Minimum Mold Thickness MM 160/220 Opening Stroke MM 200 Open Daylight MM 360/420 Max.Mold Weight Kg / Ejector Force Ton 1.3 Ejector Stroke MM 35

ELE.UNIT

Max.Hydraulic Pressure Kg/cm2 140 Pump Output l/min 41 Oil Tank Capacity L 138 Cooling Water Consumption I/h 600-800 Electric Power Kw 5.5 Barrel Heating Power Kw 2.4 Total Wattage Kw 7.9

OTHERS Machine Dimension(Approx.) M 1.6x1.05x2.45 Machine Weight(Approx.) Kg 1400 Specifications are subject to change without prior notice.

Finished Products Display

PROFESSIONAL TEAM GLOBALIZATION SERVICES

Dongguan Tiancheng Machinery Co., Ltd., established in 1999, locates in Dongguan City (world-famous manufacture base), covers an area more than 8000m, owns advanced facilities, professional technical team & modern manage system. Product range covers from standard type, rotary, slip form, two color, Bakelite, BMC, liquid silicone, to plastic injection around equipments such as material dryer, suction feeder, mould design, automatic mechanical.

1. Super strong R&D, with several Patent Applications of Automatic Production Auxiliary Equipments (injection molding machine around).

2. Thrifty/Simple working style, Aggressive investment in production facilities & work flow planning, offer customer highly qualified machines & moulds at most reasonable price.

3. Customer mainly covers over Asia, Southern America, Eastern Europe, including Samsung, Flextronics, COSONIC, CLIP, etc. Engineers are available to serve overseas. One- year Warranty as basic, plus Worry-free After-sales Service (online messager/email/phone call Q&A, detail Graphic instructions, troubleshooting demonstration video, etc.).

Our Services:

1. Recommend on needs:

We offer information of product/molds dimensions/operating materials/technical detas/budget,we will make a recommendation and comparison molds to you.

2. We provide OEM service to our customers.

3. Warranty & after-sales service.

We provide one year warranty for machine & accessories, delivery charges of parts replacement on customers.We can also provide overseas maintenance support to pur customers, flights & living costs on customer.

4. Reply your enquiry in 24 working hours, any time you can contact us.

a) How can I pay you?

A: After you confirm our PI, you can pay through T/T (HSBC bank) and L/C.

b) What`s the order procedure?

A: 1. First we discuss order details, production details by e-mail or online consultation (Wechat / WhatsApp).

2. Then we issue an PI for your confirmation. Customer should makes payment deposit before we enter production.

3. After we receive the deposit, we start to process the order.

4. Before production has been finished, we will contact you for machine details video to confirm and you should prepare the rest payment.

5. After the rest payment has been received, we start to ship out the goods for you.

c) How can I place order?A: You can contact us by email about your order details, or place order on line.

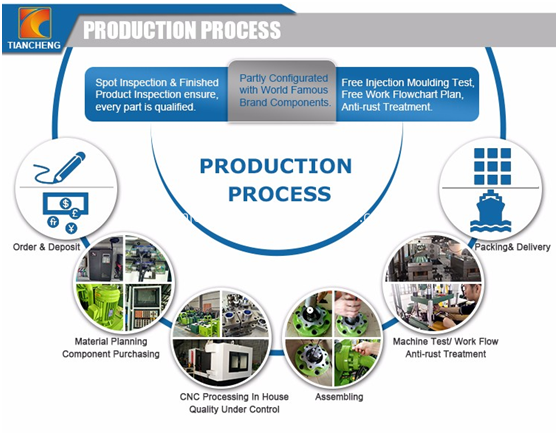

d) How do you control quality through production process?

A: We have spot inspection and finished product inspection. We check the semi-finished goods before they go into next step production process.

Sara Ting

Export Manager

TianCheng

Wechat: +86 13922548377 (Mobile)

WhatsApp: +86 18024336689

1 Yuhua Rd., Juzhou Vil., Shijie Tn.,

Dongguan, Guangdong, China

Product Categories : Plastic Injection Molding Machine Customer Applications > Dental Fross Pick Injection Machine